The hospital doors we see in hospital wards, operating rooms, etc. All belong to special medical doors. Medical doors are different from the automatic doors we usually see in terms of material and fire resistance. So what is the difference between medical doors and automatic doors? Have other hospital door control functions been added? Why don't we use automatic hospital doors in our daily lives and work?

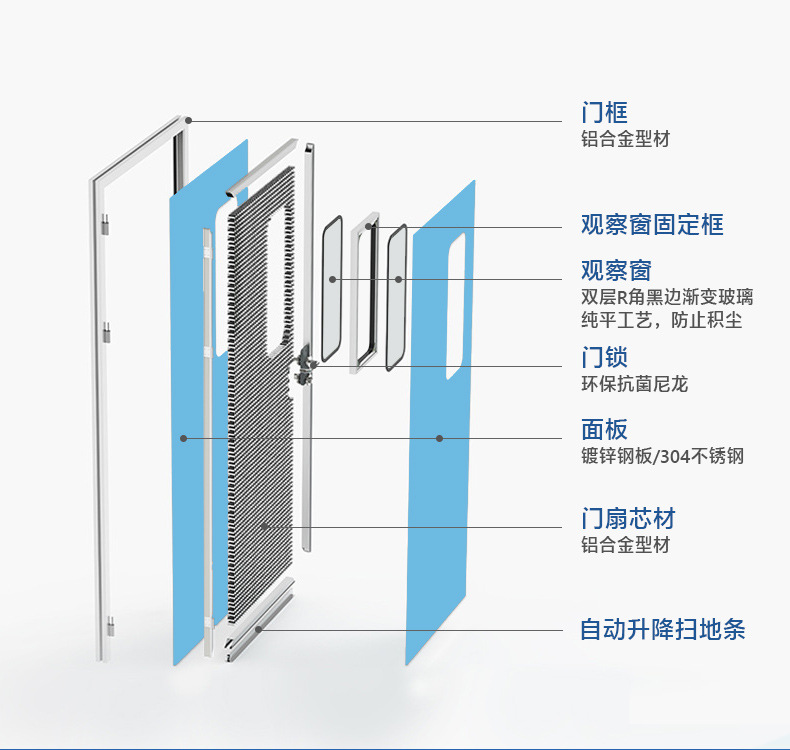

The hospital's automatic doors are designed with surface sprayed stainless steel or aluminum plates and equipped with sealing strips, meeting the hygiene requirements for hospital use. The automatic door is equipped with special rubber seals around the movable door. When the door is closed, they can reliably attach to the door frame to ensure the airtightness of the door. The design of the automatic door body adopts large stainless steel panels, aluminum-plastic panels, PVC steel plates or fireproof panels sprayed on the surface, and is equipped with sealing strips, which meet the hygiene requirements for hospital use. The door body can be selected in multiple colors.

1. Medical door guidance system: It is a guiding and positioning device at the lower part of the medical door leaf, which prevents the occurrence of front and rear medical doors during the operation of the medical door leaf. When opening and closing the medical door, the working process is as follows: When the medical door sensor (transducer) detects someone entering, it sends a pulse signal to the main controller. After passing through the main controller, it judges the operation of the motor, pays attention to the motor speed, informs the running time, and slowly enters the force application state. The motor runs forward with current (electron flow), and power (referring to the work done by an object in a unit of time) is transmitted to the belt. The belt transmits power to the sling system that opens the hospital door; The opening of the medical door leaf is determined by the controller. For example, when the automatic medical door is closed, the motor is notified to reverse and the automatic medical door is closed;

2. Medical door track: Similar to train tracks, the wheel restraint system of the door leaf lifting device is designed according to specific directions;

3. Medical door switch power motor: main power supply, acceleration and deceleration control door operation;

4. Hanging wheel suspension system for special medical doors: While moving the door leaf, the medical traction drives the door to operate;

5. Medical door sensor: responsible for collecting external signals, such as human eyes. When a moving object is within its working range, it is the pulse signal of the main controller;

6. Dedicated medical door synchronous belt (some manufacturers use V-belt): used for transmitting motor power and pulling the lifting device system of walking blades;

7. Special medical door controller: It is the command center of automatic medical doors, which plans large integrated blocks through internal program instructions to command the operation of vehicles or electric lock systems. At the same time, the main controller adjusts the speed to open the opening range of the hospital door;

Have you gained any understanding of the application of medical doors in clean spaces through the above introduction? It is precisely because of the above characteristics that medical doors are not suitable for general environments and are more suitable for places with high cleaning requirements, as the cost is too high and the use is also relatively troublesome. For places with general cleaning requirements, using medical doors is a burden.