Due to its excellent airtightness, airtight doors are often used in places with high airtightness requirements such as hospitals. Do you have such a question? Is the airtightness of airtight doors related to their internal structure? What is its internal structure? How do manufacturers ensure the quality of airtight doors? Below, the airtight door manufacturer will take you to learn more, hoping to help you!

1、 Medical airtight door quality assurance, reasonable price

The opening and closing of the airtight door in the operating room is driven by a motor, greatly reducing the labor intensity and traffic efficiency of the entrance and exit. By adopting advanced control technology and safety protection measures, the access air door is safer and more reliable.

The sealing and energy-saving performance of airtight doors. No matter where the airtight door of the operating room is turned, it automatically closes outside and inside, reducing heat loss, minimizing dust intrusion, increasing airtightness, and saving energy. Other types of medical airtight doors can quickly and automatically close the door and adjust the opening width of the door leaf, which also increases their airtightness and energy-saving performance.

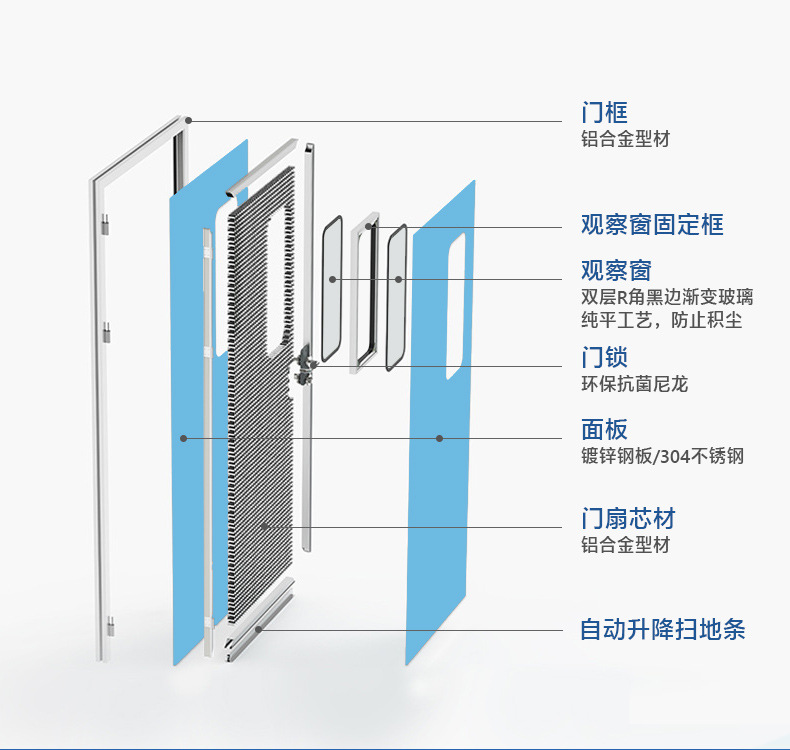

2、 Internal composition of the airtight door structure in the operating room

At present, medical airtight doors are mainly divided into two categories. One is inorganic lead glass, which was widely used in China at that time; Another type is organic lead glass, which has higher impact resistance than inorganic lead glass, but is not resistant to alkali and alcohol. The chemical plant used to produce organic lead glass, but stopped production a few years ago. Although there are manufacturers in China, the physical functionality and protective quality of the products are not ideal.

The airtight door of the operating room is mainly used as an observation window for X-ray rooms, computer rooms, computer rooms, etc. And used for manufacturing lead glass. In addition to the above-mentioned uses, organic radiation resistant lead glass is widely used in the manufacture of various protective lead screens and other protective equipment, such as face shields and blinds, due to its ease of processing, light weight, strong impact resistance, and good transparency.

For radiation protection planning, it is necessary to follow radiation protection optimization standards to maintain the exposure dose of workers and subjects at a reasonable low lead clothing level. The "guide door" refers to the entrance and exit of a building or equipment, which can be opened and closed at the entrance and exit. Briefly introduce the sliding protective door.

Internally composed of steel frame, pure lead plate, special density board, strong anti-corrosion adhesive, insulation materials, and anti-theft lock; The appearance can be made of imported luxury stainless steel, color steel plate, and fireproof board as raw materials. There are 8K stainless steel mirror plate edges on all four sides, 8K stainless steel mirror plate decorative strips in the center of both sides, and stainless steel frosted plate anti-collision strips below both sides; The moving wheel equipped with a power assisted sliding door handle can be operated by the sky rail or ground rail, and the rail equipment has shock absorption devices; Equipped with motor and frequency converter, with remote control; Customize door size and protection specifications according to customer requirements.

The above are some relevant information about airtight doors compiled by airtight door manufacturers. I believe that through the description in this article, you can have some understanding of airtight doors. I hope the above content can be helpful to you. In addition, if you want to learn more about related information, you can pay more attention to our website updates.